Das Wonderbook™-Peripheriegerät ist ein leichtes Buch mit einzigartigen „Augmented Reality (AR)“-Markierungen auf jeder Seite. Wenn der Spieler es in den Händen hält, fühlt es sich zwar wie ein gewöhnliches Buch an, doch ist es alles andere als normal.

Die PlayStation®Eye-Kamera erkennt das Buch und dessen Position, Entfernung und Winkel zur Kamera und kann dabei sogar die Umgebung ausblenden, um den Spieler in ein spannendes Erlebnis eintauchen zu lassen.

Video schliessenVideo ansehen

Video schliessenVideo ansehen

Unterhaltung vom Feinsten: PlayStation®3 hält ein unvergleichliches Unterhaltungsangebot für die ganze Familie bereit. Dich erwarten ungeahnte Abenteuer mit Spielen in High Definition und Stereoscopic 3D, beeindruckende Filme auf Blu-ray Disc, kostenloser Zugriff auf das PlayStation®Network und vieles mehr. Ein System, unzählige Möglichkeiten.

Mehr Infos

Mithilfe dieses Motion-Controllers tauchst du auf eine Art und Weise in ein Spiel ein, die du nie für möglich gehalten hättest. Deine Bewegungen werden sofort unglaublich genau in großartiger High Definition auf dem Bildschirm umgesetzt. Dabei spielt es keine Rolle, ob der Controller für ein spannendes Tennis-Match, wilde Schwertkämpfe oder für heiße Tänze verwendet werden soll - Jede Bewegung wird sofort 1:1 auf den Bildschirm übertragen.

Mehr Infos

PlayStation®Eye ist die innovative Kamera der nächsten Generation, die das Beste aus deinem PS3-System herausholt. Du kannst die Kamera über einen der USB-Anschlüsse an dein PlayStation 3-System anschließen und Video- und Soundqualität der Extraklasse erleben. Die Features der PlayStation®Eye-Kamera umfassen Hintergrund-Geräuschreduzierung für problemlose Spracherkennung, eine schnellere Bildrate für verbesserte Videoqualität und ein verstellbares Zoomobjektiv für das perfekte Spielerlebnis.

Mehr Infos Enhance your network coverage with signal boosters for mobile phones.

Enhance your network coverage with signal boosters for mobile phones.

ORDB – Your Valet-De-Place In The World Of Crypto Gambling And Betting.

ORDB – Your Valet-De-Place In The World Of Crypto Gambling And Betting.

Discover the allure of Hot Fruit Game, where simple yet engaging gameplay meets the excitement of potential big wins.

Discover the allure of Hot Fruit Game, where simple yet engaging gameplay meets the excitement of potential big wins.

Acesse a Tigre 777 Plataforma para uma experiência de jogo inesquecível, com uma vasta seleção de jogos e oportunidades de ganho sem igual.

Acesse a Tigre 777 Plataforma para uma experiência de jogo inesquecível, com uma vasta seleção de jogos e oportunidades de ganho sem igual.

Online casinos Kenya are the hotspots for gamers seeking big wins and endless fun.

Online casinos Kenya are the hotspots for gamers seeking big wins and endless fun.

Die PlayStation®Eye-Kamera sollte unterhalb des Fernsehers platziert werden. Die Kamera sollte auf „Weitwinkelansicht“ stehen und möglichst weit nach unten geneigt werden.

Die Kamera sollte 70 bis 100 cm über dem Boden in einer zentralen Position platziert werden.

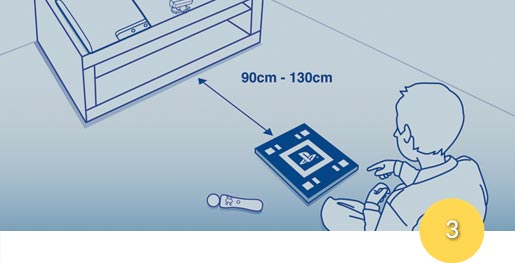

Das Wonderbook™ sollte geschlossen auf dem Boden platziert werden, sodass es am unteren Rand des Fernsehbildschirms erscheint.*

* entspricht einer Entfernung von 90 bis 130 cm zur PlayStation®Eye-Kamera.

Der Raum sollte gleichmäßig beleuchtet und so hell wie möglich sein. So kann das Buch besser erkannt werden. Es sollten sich keine Strahler im Raum befinden, da diese dunkle Schatten werfen.

Mit Hilfe des PlayStation®Move-Motion-Controllers kannst du uralte Fossilien ausgraben, die direkt aus deinem Wonderbook zu kommen scheinen.

Vervollständige das Skelett der prähistorischen Giganten und erlebe hautnah, wie sich diese riesigen Tiere um dich herum bewegen und mit dir interagieren. Aber pass auf! Manche Dinosaurier waren zu Lebzeiten gefürchtete Räuber, vor denen du dich besser verstecken solltest.

Bundle wählen & bestellen